- Overview

- Related Products

Product Description

Wanli OEM Skin Touch Feel PETG Furniture Decorative Film

Material |

PETG |

Usage |

MDF boards, cabinets, doors, walls, floor, etc. |

Application |

Hotels, apartments, offices, home,hall, mall, hospital,interior furniture, etc. |

Thickness |

0.18mm - 0.6mm |

Width |

1240mm ,1250mm(regular) ,1260mm ,1350mm ,1400mm are available |

Surface |

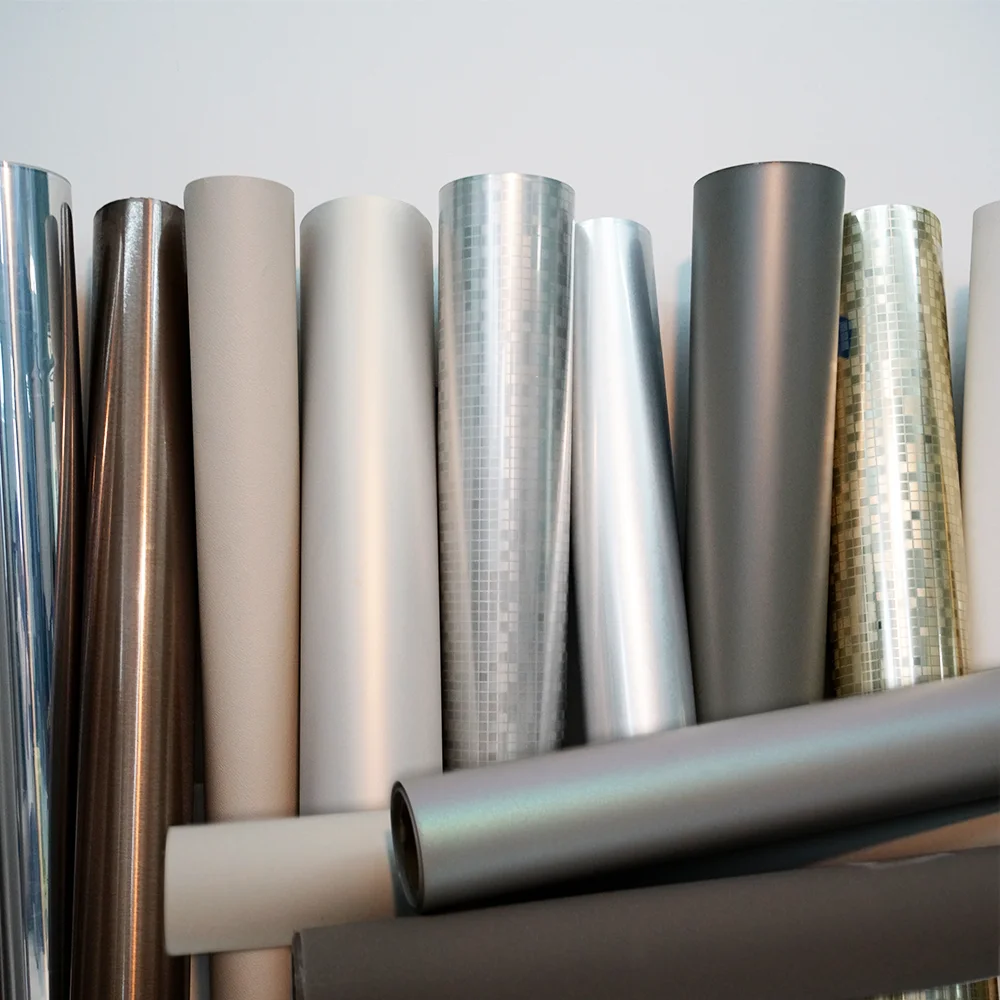

Smooth / Embossed / High glossy/ Matte/ Metallic Brushed/ Solid Color with the protective film |

Delivery time |

2-3 weeks after receiving 30% deposit. |

Payment |

T/T, Western Union, Credit Card, Paypal...... |

Features |

1. Scratch resistance, Waterproof and Fireproof |

2. Unfading & Easy to clean |

|

3. High Saturation, 3D Touch Feeling |

|

4. Oil, Acid and Alkali resistance |

|

5. Explosion-Proof, Heat Insulation,ECO-Friendly |

|

Thickness suggested |

1. Interior door: 0.12mm-0.18mm |

2. Furniture: 0.14mm-0.35mm |

|

3. Steel door: 0.14mm-0.2mm |

|

4. Kitchen cabinet door: 0.25mm-0.5mm |

|

5.Wall panel/window sill/door frame: 0.12mm-0.2mm |

Customize PETG Film

Customized solid color, stone, wood, embossed, glitter silver, brushed, etc.

Surface Treatment :high gloss, skin feel, matte, etc.

Wide Application

Apartmemt, Office, Home, Hotel,Hall , Mall, Hospital, etc

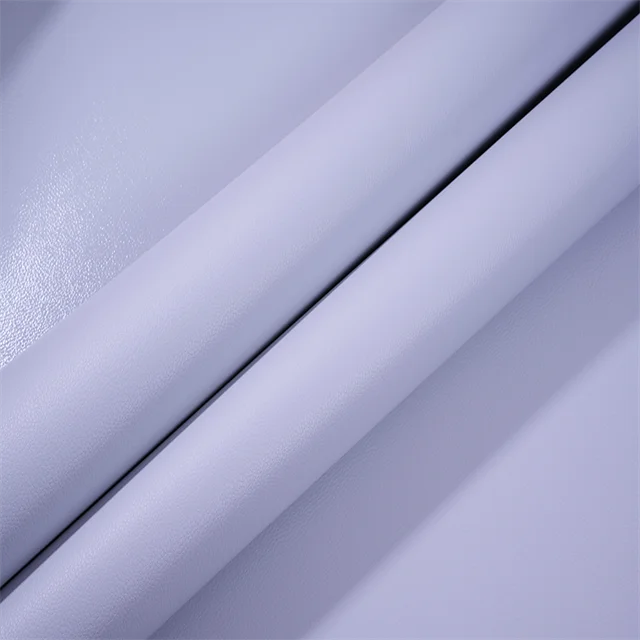

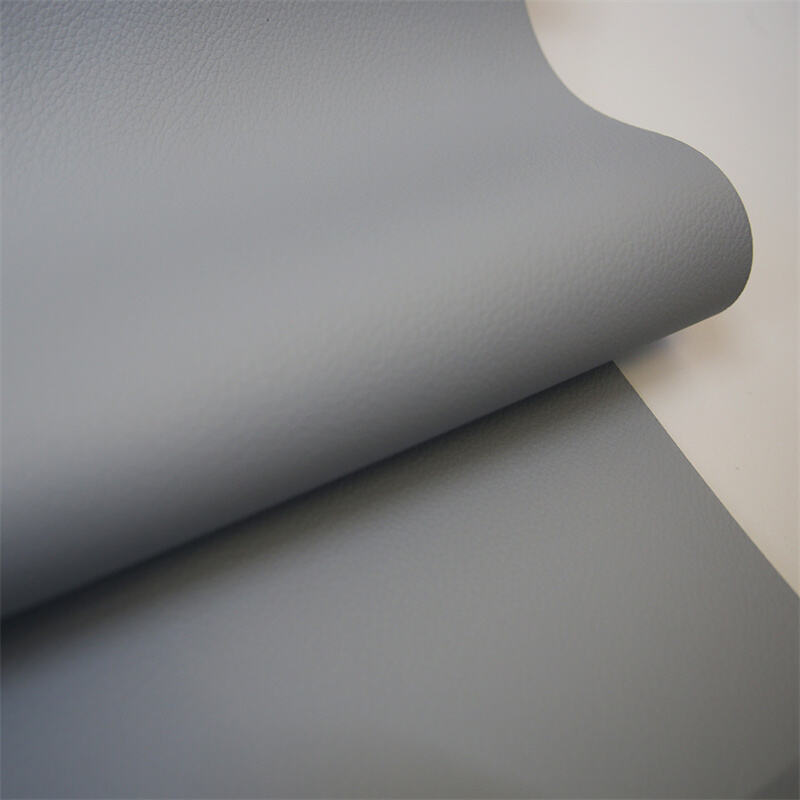

Sample Show

Formaldehyde Free & Environmental Friendly

Company Profile

Heyuan Wanli Technology Co., Ltd.

Wanli Group was founded in 1990 and is an environmentally friendly, technological, and innovative technology enterprise.

Heyuan Wanli Technology Co., Ltd. extends its expertise in mobile phone backboards to the development of 5E multi effect panel films; We can customize various colors such as solid, stone, wood, embossed, glitter silver, brushed, etc. The surface can be made with high gloss, skin feel, matte, and other processes. We have a 60000 square meter industrial park, a 10000 level dust-free production workshop, multiple fully automatic extrusion production lines, and an integrated manufacturer of high gloss skin coating equipment, which can reduce transportation costs and ensure product quality to a greater extent, achieving the business philosophy of creating maximum value for customers. Strong R&D capabilities are the software and hardware support for technological innovation. Equipped with excellent personnel and an industry expert technical team, we can improve the product quality standards required by customers and create maximum value for them.

Wanli Technology will adhere to the spirit of diligence and perseverance, continue to develop in multiple successful directions such as strengthening research and development, increasing production capacity, and expanding product market share. While committed to consolidating and enhancing industry leadership, Wanli Technology will strive to become the world's first environmentally friendly home film material research and development manufacturer.

Heyuan Wanli Technology Co., Ltd. extends its expertise in mobile phone backboards to the development of 5E multi effect panel films; We can customize various colors such as solid, stone, wood, embossed, glitter silver, brushed, etc. The surface can be made with high gloss, skin feel, matte, and other processes. We have a 60000 square meter industrial park, a 10000 level dust-free production workshop, multiple fully automatic extrusion production lines, and an integrated manufacturer of high gloss skin coating equipment, which can reduce transportation costs and ensure product quality to a greater extent, achieving the business philosophy of creating maximum value for customers. Strong R&D capabilities are the software and hardware support for technological innovation. Equipped with excellent personnel and an industry expert technical team, we can improve the product quality standards required by customers and create maximum value for them.

Wanli Technology will adhere to the spirit of diligence and perseverance, continue to develop in multiple successful directions such as strengthening research and development, increasing production capacity, and expanding product market share. While committed to consolidating and enhancing industry leadership, Wanli Technology will strive to become the world's first environmentally friendly home film material research and development manufacturer.

Shenhzen Exhibition Center

Heyuan Wanli Factory

Office

Sample Room

Culture Center

Meeting Room

Wanli Factory Show

PETG-Film Production Process

Modern Automaic Production Machine for Petg Film

Cooperation Partner

Honor & Certificates

Customer Services

What's PETG film?

PETG Film, 5E Multi-Effect Panel Film

PETG Film, 5E Multi-Effect Panel Film is suitable for environmental protection flat film on furniture surface. The products use green and environmentally friendly materials, which have excellent properties such as wear resistance, stain resistance, and yellowing resistance, making the furniture surface present a variety of fashionable and beautiful visual effects.

Structure:

1. Hardening layer: strategically cooperate with mobile phone film hardening manufacturers to apply the surface treatment process of mobile phone film to the surface of decorative materials.

2. Substrate layer: a. Main material: PETG material, PETG is a non-crystalline copolyester, which has passed the US FDA certification standard for food contact. It is a degradable material with high

Structure:

1. Hardening layer: strategically cooperate with mobile phone film hardening manufacturers to apply the surface treatment process of mobile phone film to the surface of decorative materials.

2. Substrate layer: a. Main material: PETG material, PETG is a non-crystalline copolyester, which has passed the US FDA certification standard for food contact. It is a degradable material with high

transparency, high toughness, high Gloss, impact resistance, friction resistance, high chemical resistance and super weather resistance b. Color masterbatch: All colors are realized by adding color masterbatch, and all color masterbatches are imported from top global brands.

3. Back coating: In order to ensure the adhesion, the back of the material adopts a special treatment process to achieve the effect of back coating.

3. Back coating: In order to ensure the adhesion, the back of the material adopts a special treatment process to achieve the effect of back coating.

Advantage

1. In terms of color, the white color with different temperature and temperature is the color of "no mistake" in home decoration; the gray color that represents a gentleman can perfectly "show" the "high-end sense" that designers love; khaki, beige and other colors Replenishment brings back the feeling of "relaxed and in love". When mixed with various metal materials and stone materials, the PET series does not lose its price, and can even offset the coldness and rigidity of the metal and stone materials themselves.2. In terms of touch, matte PET is often called skin-sensitive film and anti-fingerprint film. This "baby-skin-soft" feel makes PET a perfect material for wardrobes, and it fits well with the "homey" ideal that most designers want to create.

3. In terms of price, the door panel made of PET material is also very "beautiful" in terms of price. The relative cheapness of PET mainly comes from the material itself and the custom home furnishing industry that is increasingly moving towards Industry

4. First of all, the thickness of PET on the market is mostly between 0.3mm and 0.6 mm. The thinner thickness and relatively affordable raw material prices make PET sheets not expensive. At the same time, thanks to its thinner thickness, the general PET is a roll material, which greatly improves its pressing efficiency.

4. In terms of environmental protection, compared with the chlorine element contained in PVC film, PET is the same as acrylic, and its material itself is only composed of three elements: C, H, and O. In the market, people often cannot tell the difference between PVC film and PET film, and the two materials are indeed very close. In fact, it is very simple, as long as the two are ignited, if there is a pungent smell, it is PVC, and if there is no pungent smell, it is PET. As the country's requirements for environmental protection are getting higher and higher, baking varnish products with relatively serious pollution, relatively complicated processes, and relatively large labor consumption are facing unprecedented challenges, which brings unprecedented opportunities for the development of PET materials.

Contact Us

Contact us for free sample and customize your products