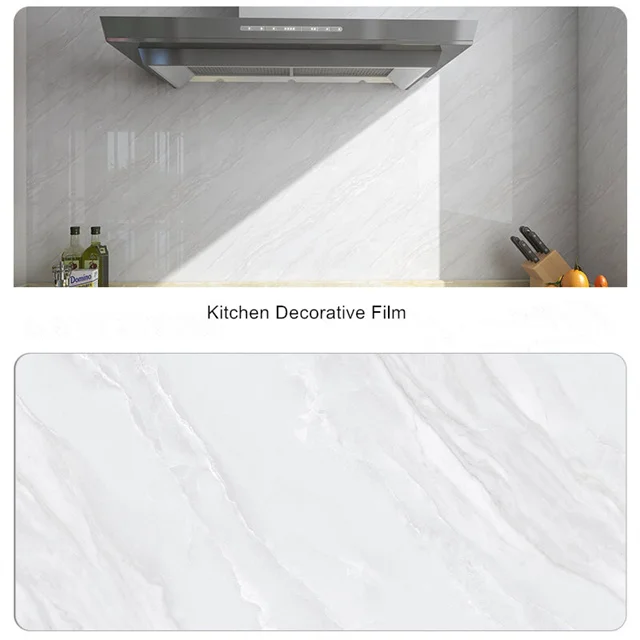

White black high glossy marble pet petg decorative film for furniture sticker faced MDF cabinet

- Overview

- Related Products

Product Description

Wanli OEM Marbel Design PETG Furniture Decorative Film

Material |

PETG |

Usage |

MDF boards, cabinets, doors, walls, floor, etc. |

Application |

Hotels, apartments, offices, home,hall, mall, hospital,interior furniture, etc. |

Thickness |

0.18mm - 0.6mm |

Width |

1240mm ,1250mm(regular) ,1260mm ,1350mm ,1400mm are available |

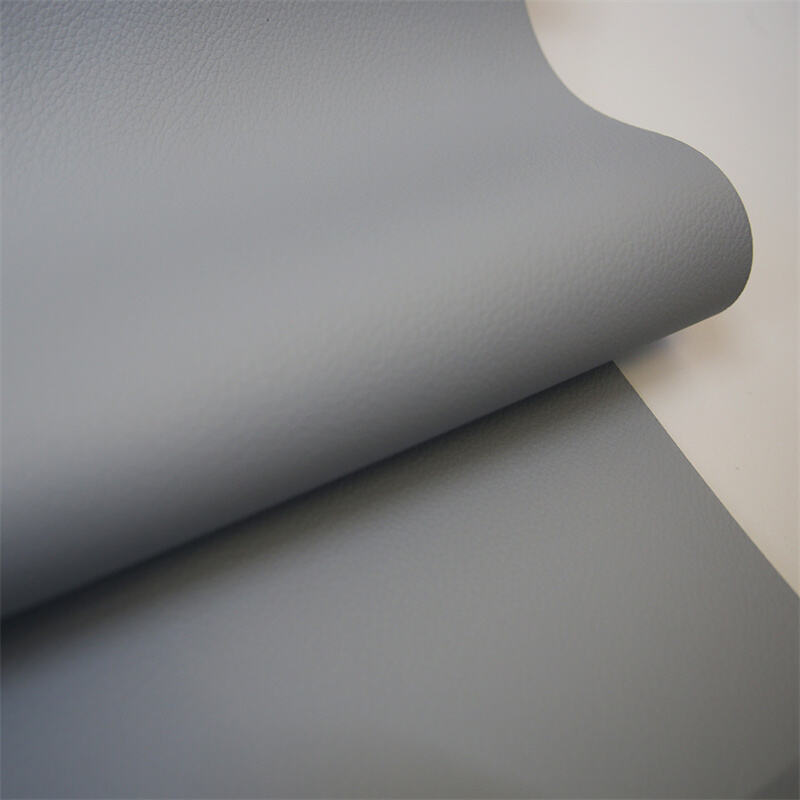

Surface |

Smooth / Embossed / High glossy/ Matte/ Metallic Brushed/ Solid Color with the protective film |

Delivery time |

2-3 weeks after receiving 30% deposit. |

Payment |

T/T, Western Union, Credit Card, Paypal...... |

Features |

1. Scratch resistance, Waterproof and Fireproof |

2. Unfading & Easy to clean |

|

3. High Saturation, 3D Touch Feeling |

|

4. Oil, Acid and Alkali resistance |

|

5. Explosion-Proof, Heat Insulation,ECO-Friendly |

|

Thickness suggested |

1. Interior door: 0.12mm-0.18mm |

2. Furniture: 0.14mm-0.35mm |

|

3. Steel door: 0.14mm-0.2mm |

|

4. Kitchen cabinet door: 0.25mm-0.5mm |

|

5.Wall panel/window sill/door frame: 0.12mm-0.2mm |

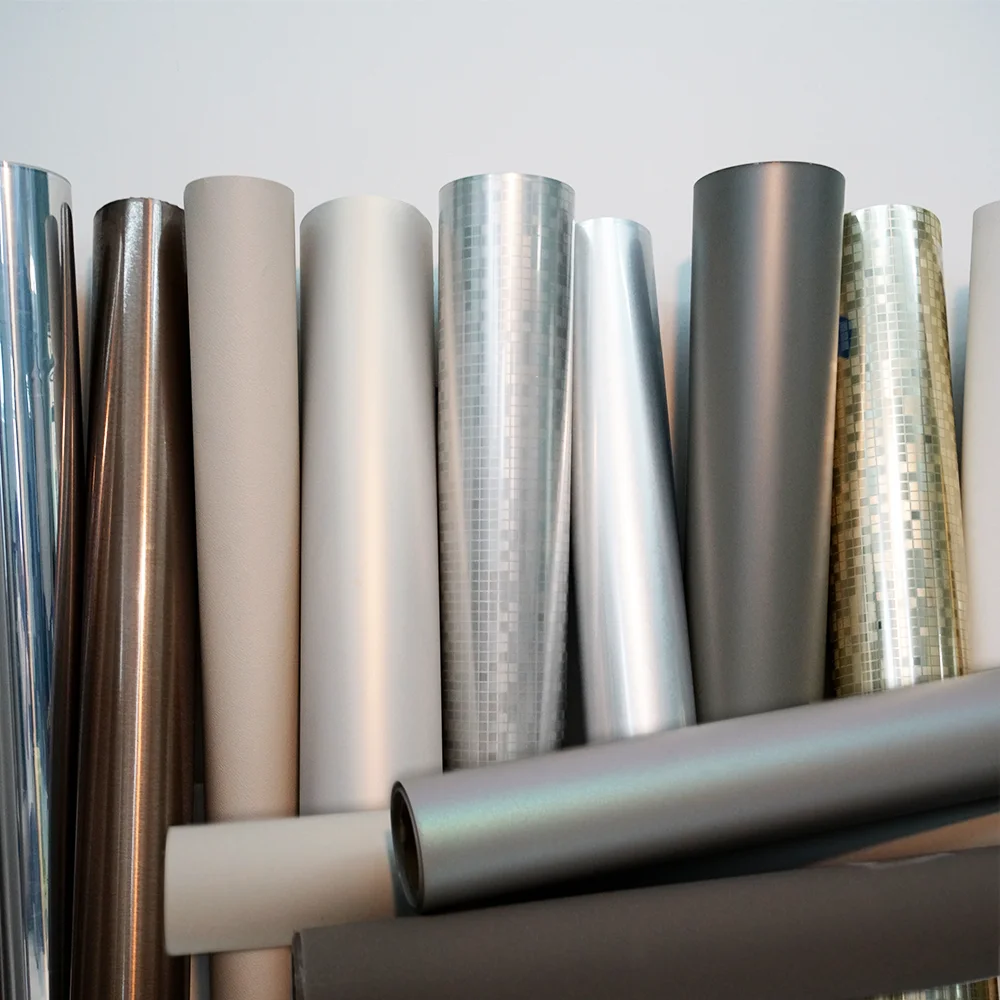

Customize PETG Film

Customized solid color, stone, wood grain, embossed, glitter silver, brushed, etc.

Surface Treatment :high gloss, skin feel, matte, etc.

Wide Application

Apartmemt, Office, Home, Hotel,Hall , Mall, Hospital, etc

Sample Show

Morden Design & Protective Film

Formaldehyde Free & Environmental Friendly

Company Profile

Heyuan Wanli Technology Co., Ltd.

Wanli Group was founded in 1990 and is an environmentally friendly, technological, and innovative technology enterprise.

Heyuan Wanli Technology Co., Ltd. extends its expertise in mobile phone backboards to the development of 5E multi effect panel films; We can customize various colors such as solid, stone, wood, embossed, glitter silver, brushed, etc. The surface can be made with high gloss, skin feel, matte, and other processes. We have a 60,000 square meter industrial park, a 10,000 level dust-free production workshop, multiple fully automatic extrusion production lines, and an integrated manufacturer of high gloss skin coating equipment, which can reduce transportation costs and ensure product quality to a greater extent, achieving the business philosophy of creating maximum value for customers. Strong R&D capabilities are the software and hardware support for technological innovation. Equipped with excellent personnel and an industry expert technical team, we can improve the product quality standards required by customers and create maximum value for them.

Wanli Technology will adhere to the spirit of diligence and perseverance, continue to develop in multiple successful directions such as strengthening research and development, increasing production capacity, and expanding product market share. While committed to consolidating and enhancing industry leadership, Wanli Technology will strive to become the world's first environmentally friendly home film material research and development manufacturer.

Heyuan Wanli Technology Co., Ltd. extends its expertise in mobile phone backboards to the development of 5E multi effect panel films; We can customize various colors such as solid, stone, wood, embossed, glitter silver, brushed, etc. The surface can be made with high gloss, skin feel, matte, and other processes. We have a 60,000 square meter industrial park, a 10,000 level dust-free production workshop, multiple fully automatic extrusion production lines, and an integrated manufacturer of high gloss skin coating equipment, which can reduce transportation costs and ensure product quality to a greater extent, achieving the business philosophy of creating maximum value for customers. Strong R&D capabilities are the software and hardware support for technological innovation. Equipped with excellent personnel and an industry expert technical team, we can improve the product quality standards required by customers and create maximum value for them.

Wanli Technology will adhere to the spirit of diligence and perseverance, continue to develop in multiple successful directions such as strengthening research and development, increasing production capacity, and expanding product market share. While committed to consolidating and enhancing industry leadership, Wanli Technology will strive to become the world's first environmentally friendly home film material research and development manufacturer.

Shenhzen Wanli Exhibition Center

Heyuan Wanli Factory

Shenzhen Wanli Factory

Sample Room

Culture Center

Meeting Room

Modern Automaic Production Machine & Line for Petg Film

About PETG Film

GAG PETG Film Introduction

GAG decorative film is a three layer composite product. The three-layer composite film produced by coextrusion of the intermediate layer APET and the upper and lower layers PETG raw materials in a proper proportion, after special coating treatment, is particularly suitable for the decorative building materials veneer bonded by high-frequency heat sealing and glue.

Product Advantages:

1. It has high tenacity and transparency, no cracking, no discoloration, no whitening when bending;

2. Good acid resistance or chemical and oil resistance;

3. Good processing property, good fire resistance, no toxic gas is discharged after combustion;

4. The product has good stability, moisture-proof, non oxidation and no smell;

5. Good protection, wear resistance, scratch resistance, corrosion resistance, easy cleaning and other characteristics, extending the service life of the product;

6. Good heat resistance, resistant to thermal deformation and low shrinkage;

7. Good forming speed and easier secondary processing capability;

8. Low haze and high gloss, good printing ability.

Product Advantages:

1. It has high tenacity and transparency, no cracking, no discoloration, no whitening when bending;

2. Good acid resistance or chemical and oil resistance;

3. Good processing property, good fire resistance, no toxic gas is discharged after combustion;

4. The product has good stability, moisture-proof, non oxidation and no smell;

5. Good protection, wear resistance, scratch resistance, corrosion resistance, easy cleaning and other characteristics, extending the service life of the product;

6. Good heat resistance, resistant to thermal deformation and low shrinkage;

7. Good forming speed and easier secondary processing capability;

8. Low haze and high gloss, good printing ability.

Honor & Certificates

Cooperation Partner

Customer Services

Contact Us

Contact us for free sample and customize your products